Ceramic membranes (Porous Ceramic Membrane & tubular ceramic membrane) are available for microfiltration, ultrafiltration and nanofiltration as single-channel or multiple-channel elements with channel diameters between 2 and 16mm.

Their main characteristics of porous tubular ceramic membrane

-

Consistent pore size;

-

Very narrow mean pore-size distribution;

-

Long and reliable lifetime;

-

High permeate flux;

-

Greater void area per unit area of filtration surface;

-

High stability to organic media;

-

High-pressure resistance, high-temperature resistance;

-

Rigid with no creep or deformation;

-

Stable over a wide pH range;

-

Membranes bonded to substrate by strong ceramic bonds;

-

Corrosion & abrasion resistant;

-

Insensitive to bacterial action;

-

Can be repeatedly sterilized by steam or chemicals;

-

Ability to backwashed;

-

The possibility of regeneration after fouling;

-

Can process highly viscous fluids;

Contact us now for more details about

China membrane provided by one of leading ceramic membrane manufacturers Jiuwu and the ceramic membrane price!

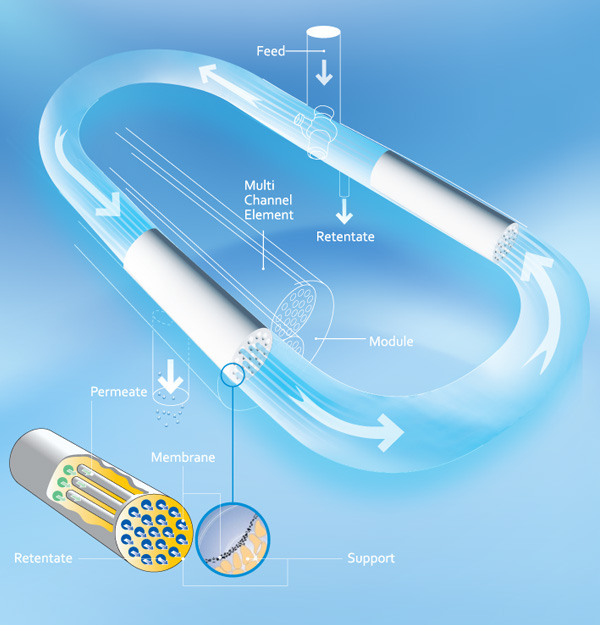

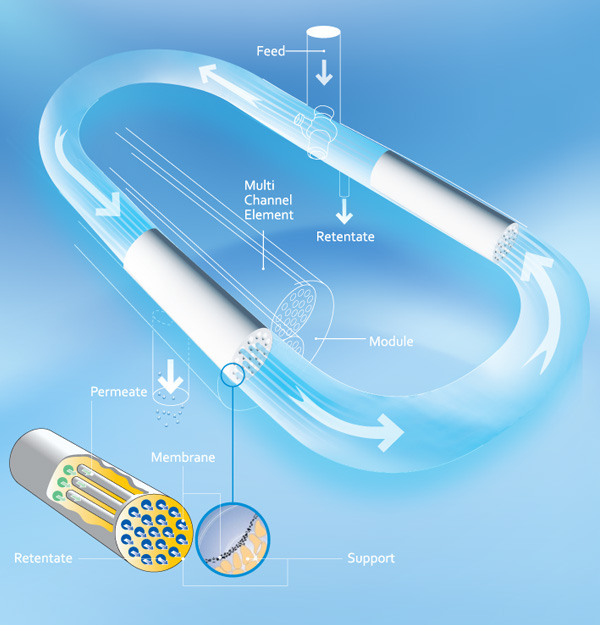

The principle of porous tubular ceramic membrane

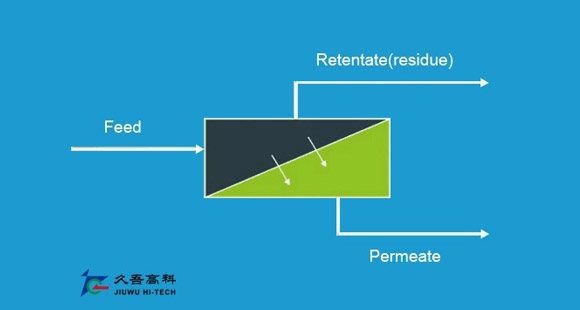

The principle of the filtration is based on two opposing effects: on the one hand, the particles are transported by the filtration flux to the membrane where they cause an increase in concentration; on the other hand, concentration differences are again reduced by the turbulence of the cross-flow and by Brownian motion of the particles. Ceramic membrane separation has greatly improved work efficiency and quality.

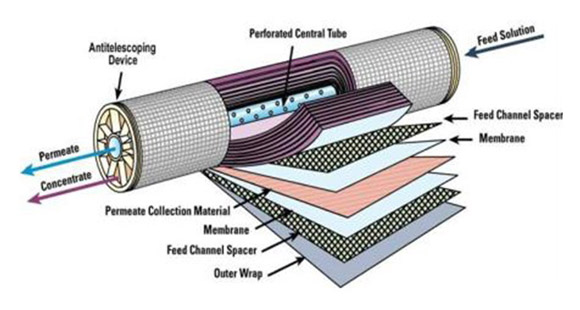

During filtration by means of ceramic membranes made by JIUWU ceramic membrane manufacturer, the medium to be filtered flows through the channels of the membrane support. All particles whose size exceeds the pore radius of the membrane are retained. The particles /molecules build up in the concentrate. The filtrate permeates through the pores and depending on the procedure is subjected to subsequent process stages. This filtering method is also called "cross-flow filtration" or "dynamic filtration". Cross-flow management can achieve stable fluxes. Still, the cleaning of cross-flow installations needs to be applied from time to time. Cleaning is performed by means of backward flushing or chemical cleaning. There are various ceramic membranes for water treatment in the market, while JIUWU ceramic membranes for wastewater treatment perform very well. Learn more about pilot ceramic

membrane technology and ceramic membrane design here!

The principle of cross-flow filtration in porous tubular ceramic membrane

How do ceramic membranes work?

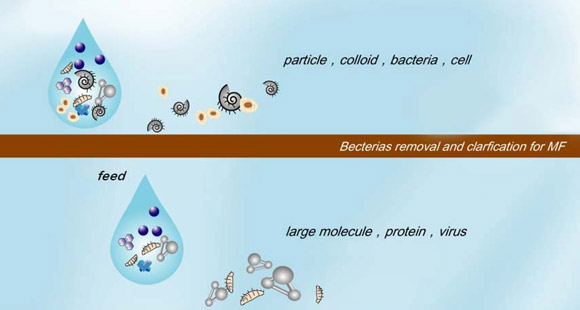

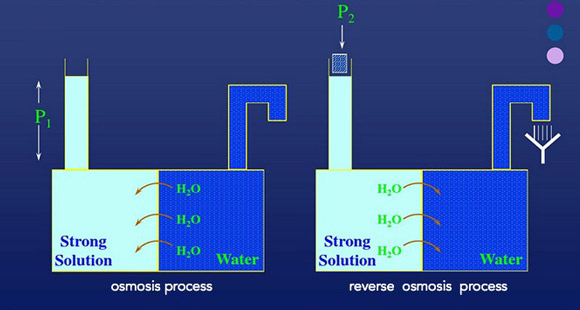

Ceramic membranes are a type of filtration membrane made from inorganic materials such as aluminum oxide, zirconium oxide, and titanium oxide. They work by selectively allowing certain substances to pass through while blocking others based on their size and charge.

Ceramic membranes are characterized by their small pore size, typically in the range of 0.1 to 1 micron, which allows them to filter out particles and molecules that are larger than the pore size. This makes them particularly useful for applications that require high levels of filtration, such as water treatment, gas separation, and biotechnology.

The separation mechanism of ceramic membranes is based on a combination of size exclusion and electrostatic repulsion. As fluid flows through the membrane, particles and molecules that are larger than the pore size are blocked, while smaller particles and molecules are allowed to pass through. The charged surface of the ceramic membrane can also repel particles and molecules that have the same charge, further enhancing the separation efficiency.

Ceramic membranes are known for their high mechanical strength, chemical resistance, and thermal stability, which make them suitable for a wide range of industrial applications. They are also easy to clean and can be used for extended periods of time without losing their filtration properties, making them a cost-effective and sustainable solution for many filtration needs.

English

English 한국어

한국어 français

français русский

русский Español

Español

JIUWU Ceramic Membrane Products

JIUWU Ceramic Membrane Products

Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808

No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808